18 Jul,2025

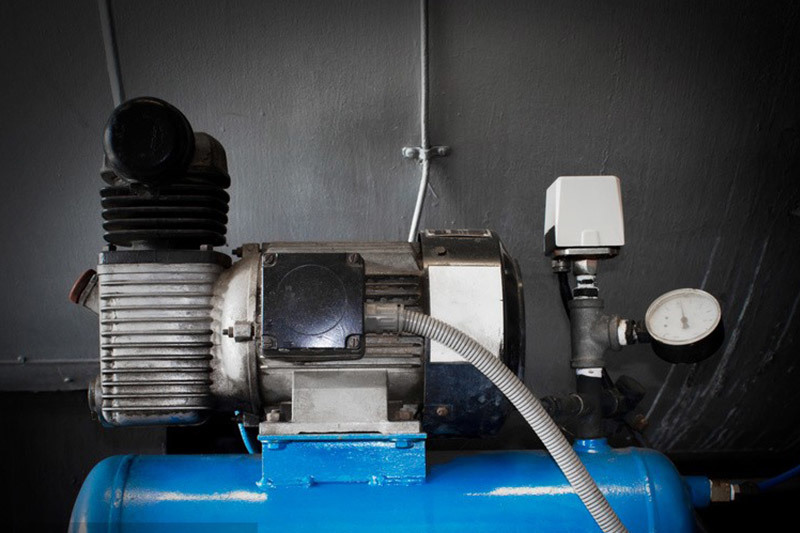

Air Compressors for the Pharmaceutical Industry: Essential Insights

In the pharmaceutical industry, air compressors play a pivotal role in various applications, from powering equipment to ensuring sterile environments. The precision and reliability of air compressors are paramount, as any contamination or deviation from standards can compromise product quality and safety. Understanding the types and functions of air compressors can help professionals in the indust

In the pharmaceutical industry, air compressors play a pivotal role in various applications, from powering equipment to ensuring sterile environments. The precision and reliability of air compressors are paramount, as any contamination or deviation from standards can compromise product quality and safety. Understanding the types and functions of air compressors can help professionals in the industry make informed decisions.

There are several types of air compressors used in the pharmaceutical sector, including rotary screw compressors, piston compressors, and scroll compressors. Each type has its advantages and is suited for specific applications. For instance, rotary screw compressors are known for their efficiency and continuous operation, making them ideal for large-scale production environments. On the other hand, piston compressors are often used for smaller tasks where high pressure is required.

One of the primary applications of air compressors in the pharmaceutical industry is in the production of medical devices and pharmaceuticals. Compressed air is essential for driving pneumatic tools, operating filling machines, and even in the formulation of certain products. Moreover, in cleanroom environments, air compressors help maintain air quality by providing the necessary pressure to filter and circulate air, which is crucial for preventing contamination.

When selecting an air compressor for the pharmaceutical industry, several factors should be considered. First, the quality of the compressed air is vital. Pharmaceutical operations often require air that is free from contaminants, moisture, and oil. Therefore, using oil-free air compressors or installing additional filtration systems is common practice. Additionally, understanding the required flow rate and pressure for specific applications is essential to ensure that the compressor can meet the operational demands without compromising efficiency.

Another important aspect is compliance with regulatory standards. The pharmaceutical industry is heavily regulated, and any equipment used must meet stringent guidelines to ensure safety and efficacy. Choosing air compressors that are designed with these regulations in mind can facilitate compliance and help avoid costly setbacks.

Maintenance is another critical consideration for air compressors in the pharmaceutical industry. Regular maintenance ensures that the compressors operate efficiently and reliably, reducing the risk of downtime. Implementing a preventive maintenance program can help identify potential issues before they become significant problems, ensuring consistent performance.

In conclusion, air compressors are an integral part of the pharmaceutical industry, impacting product quality and operational efficiency. By understanding the types of compressors, their applications, and essential factors for selection and maintenance, professionals can ensure that their operations run smoothly and comply with industry standards. Whether for driving machinery or maintaining cleanroom environments, the right air compressor can make a significant difference in the pharmaceutical manufacturing process.

There are several types of air compressors used in the pharmaceutical sector, including rotary screw compressors, piston compressors, and scroll compressors. Each type has its advantages and is suited for specific applications. For instance, rotary screw compressors are known for their efficiency and continuous operation, making them ideal for large-scale production environments. On the other hand, piston compressors are often used for smaller tasks where high pressure is required.

One of the primary applications of air compressors in the pharmaceutical industry is in the production of medical devices and pharmaceuticals. Compressed air is essential for driving pneumatic tools, operating filling machines, and even in the formulation of certain products. Moreover, in cleanroom environments, air compressors help maintain air quality by providing the necessary pressure to filter and circulate air, which is crucial for preventing contamination.

When selecting an air compressor for the pharmaceutical industry, several factors should be considered. First, the quality of the compressed air is vital. Pharmaceutical operations often require air that is free from contaminants, moisture, and oil. Therefore, using oil-free air compressors or installing additional filtration systems is common practice. Additionally, understanding the required flow rate and pressure for specific applications is essential to ensure that the compressor can meet the operational demands without compromising efficiency.

Another important aspect is compliance with regulatory standards. The pharmaceutical industry is heavily regulated, and any equipment used must meet stringent guidelines to ensure safety and efficacy. Choosing air compressors that are designed with these regulations in mind can facilitate compliance and help avoid costly setbacks.

Maintenance is another critical consideration for air compressors in the pharmaceutical industry. Regular maintenance ensures that the compressors operate efficiently and reliably, reducing the risk of downtime. Implementing a preventive maintenance program can help identify potential issues before they become significant problems, ensuring consistent performance.

In conclusion, air compressors are an integral part of the pharmaceutical industry, impacting product quality and operational efficiency. By understanding the types of compressors, their applications, and essential factors for selection and maintenance, professionals can ensure that their operations run smoothly and comply with industry standards. Whether for driving machinery or maintaining cleanroom environments, the right air compressor can make a significant difference in the pharmaceutical manufacturing process.

More news