15 Jun,2025

Unlock Efficiency: Discover the Advantages of Integrated Dryer Screw Air Compressors for Your Business

Unlock Efficiency: The Benefits of Integrated Dryer Screw Air Compressors Table of Contents 1. Introduction to Integrated Dryer Screw Air Compressors 2. What Are Screw Air Compressors? 3. Advantages of Integrated Dryer Systems 4. Energy Efficiency in Operations 5. Cost Reduction and Long-Term Savings 6. Enhanced Productivity and Performance 7. Applications of Integ

Unlock Efficiency: The Benefits of Integrated Dryer Screw Air Compressors

Table of Contents

- 1. Introduction to Integrated Dryer Screw Air Compressors

- 2. What Are Screw Air Compressors?

- 3. Advantages of Integrated Dryer Systems

- 4. Energy Efficiency in Operations

- 5. Cost Reduction and Long-Term Savings

- 6. Enhanced Productivity and Performance

- 7. Applications of Integrated Dryer Screw Air Compressors

- 8. Maintenance and Reliability of Systems

- 9. Conclusion

- 10. Frequently Asked Questions

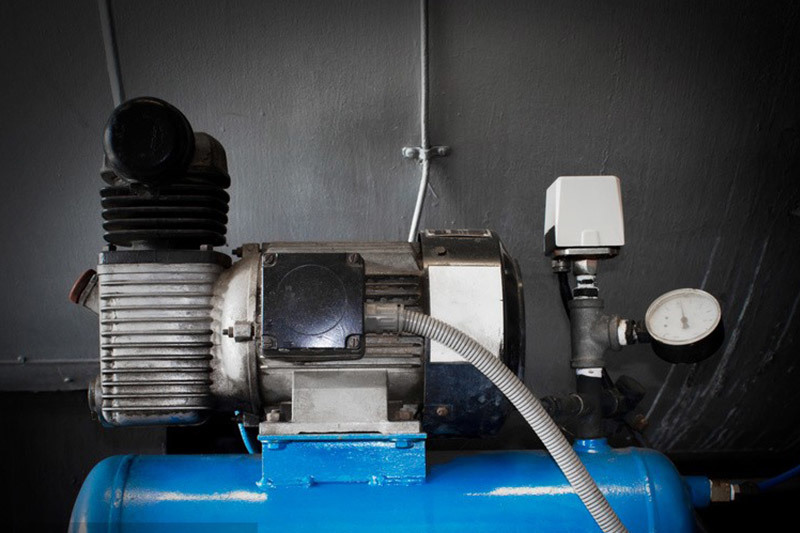

1. Introduction to Integrated Dryer Screw Air Compressors

In modern manufacturing and industrial processes, **integrated dryer screw air compressors** have become essential for maintaining optimal efficiency and productivity. These systems combine the functions of air compression and drying in one unit, offering businesses numerous advantages over traditional standalone solutions. Understanding how integrated dryer screw air compressors work and their benefits can help organizations streamline operations and reduce overhead costs significantly.

2. What Are Screw Air Compressors?

**Screw air compressors** utilize a rotary screw mechanism to compress air efficiently. Unlike piston compressors, which use reciprocating motion, screw compressors operate continuously, providing a steady supply of compressed air. This mechanism involves two intermeshed rotors that draw in air, compress it, and deliver it at high pressure. The design allows for smoother operation, reduced maintenance, and longer lifespan, making it a popular choice in various industries.

2.1 Key Features of Screw Air Compressors

- **Efficiency**: The continuous operation reduces energy consumption.

- **Durability**: Fewer moving parts result in lower wear and tear.

- **Low Noise Levels**: They operate relatively quietly compared to other types of compressors.

- **Compact Design**: Space-saving configurations make them ideal for facilities with limited room.

3. Advantages of Integrated Dryer Systems

Integrated dryer systems combine the functions of air compression and drying into a single unit. This integration offers several distinct advantages:

3.1 Space Savings

By combining two systems into one, businesses can save valuable floor space, making it easier to design efficient layouts in facilities. This is particularly beneficial for smaller operations where every square foot counts.

3.2 Simplified Installation

Integrated systems typically require less piping and fewer connections, simplifying installation. This can reduce labor costs and installation time, allowing for quicker operational readiness.

3.3 Enhanced Performance

With components designed to work together seamlessly, integrated dryer screw air compressors often provide better performance than separate units. This synergy can lead to improvements in air quality and reliability, crucial for industries requiring clean and dry air for production processes.

4. Energy Efficiency in Operations

Energy efficiency is a significant concern for many industries, and integrated dryer screw air compressors excel in this area.

4.1 Variable Speed Drive Technology

Many modern integrated systems utilize **variable speed drive (VSD)** technology. This allows the compressor to adjust its speed based on demand, significantly reducing energy consumption during low-demand periods.

4.2 Reduced Energy Loss

By eliminating the need for additional external drying equipment, integrated systems minimize energy loss associated with additional components. This can lead to substantial energy savings over time.

5. Cost Reduction and Long-Term Savings

Investing in integrated dryer screw air compressors can lead to significant cost reductions for businesses.

5.1 Lower Initial Investment

The cost of purchasing and installing a single integrated system is often lower than acquiring separate compressor and dryer units. This reduces the initial financial burden for businesses.

5.2 Decreased Operational Costs

Operating a dual-function unit can lead to lower electricity bills, reduced maintenance costs, and fewer disruptions in production. These savings can accumulate over time, making integrated systems a more economically viable option.

6. Enhanced Productivity and Performance

Efficiency and productivity are closely linked in industrial operations, and integrated dryer screw air compressors can enhance both.

6.1 Consistent Air Supply

A reliable and steady supply of compressed air ensures that production lines run smoothly. Integrated systems eliminate the risk of moisture contamination, which can disrupt operations and lead to costly downtime.

6.2 Improved Quality of Output

Clean and dry compressed air is critical for maintaining product quality. Integrated dryer systems ensure that air is free from contaminants and moisture, enhancing the overall quality of manufactured products.

7. Applications of Integrated Dryer Screw Air Compressors

Integrated dryer screw air compressors find applications across various industries, demonstrating their versatility and effectiveness.

7.1 Manufacturing and Production

Industries reliant on pneumatic tools and automation benefit greatly from the reliability and efficiency of integrated systems, ensuring uninterrupted production.

7.2 Food and Beverage Industry

In food processing, maintaining clean, dry air is essential for safety and quality. Integrated systems support compliance with industry standards while enhancing production capabilities.

7.3 Pharmaceuticals and Healthcare

Reliability and purity of compressed air are critical in the pharmaceuticals and healthcare sectors. Integrated dryer systems ensure the highest quality standards are met in production processes.

7.4 Automotive and Aerospace

In the automotive and aerospace industries, integrated dryer screw air compressors support efficient manufacturing processes, including painting, assembly, and material handling.

8. Maintenance and Reliability of Systems

Integrating compressors and dryers into a single system can enhance maintenance and reliability.

8.1 Reduced Maintenance Requirements

With fewer components to maintain, integrated systems require less frequent servicing. This translates into reduced downtime and lower maintenance costs over the system's lifespan.

8.2 Reliable Performance

Integrated systems are designed to work together, increasing reliability. Businesses can count on consistent performance without worrying about compatibility issues between separate units.

9. Conclusion

Incorporating integrated dryer screw air compressors into your operations can unlock significant efficiency and productivity gains. These advanced systems offer numerous advantages, including energy savings, cost reductions, and enhanced reliability. As industries continue to evolve, investing in technology that streamlines processes and enhances performance is critical. By choosing integrated solutions, businesses can stay competitive while ensuring their operations run smoothly and effectively.

10. Frequently Asked Questions

What is an integrated dryer screw air compressor?

An integrated dryer screw air compressor combines the functions of air compression and moisture removal in a single unit, optimizing performance and efficiency.

How does an integrated dryer screw air compressor save energy?

These compressors often incorporate variable speed drive technology, which adjusts the compressor speed based on air demand, leading to reduced energy consumption.

Are integrated dryer screw air compressors more cost-effective than separate units?

Yes, integrating these systems can lead to lower initial costs, reduced operational expenses, and long-term savings through decreased maintenance and energy bills.

What industries benefit from using integrated dryer screw air compressors?

Industries like manufacturing, food and beverage, pharmaceuticals, and automotive significantly benefit from using integrated dryer screw air compressors due to their efficiency and reliability.

How do I ensure proper maintenance of an integrated dryer screw air compressor?

Regular inspections, monitoring of air quality, and following the manufacturer’s guidelines for servicing can help maintain optimal performance and longevity of the system.

More news