30 Jun,2025

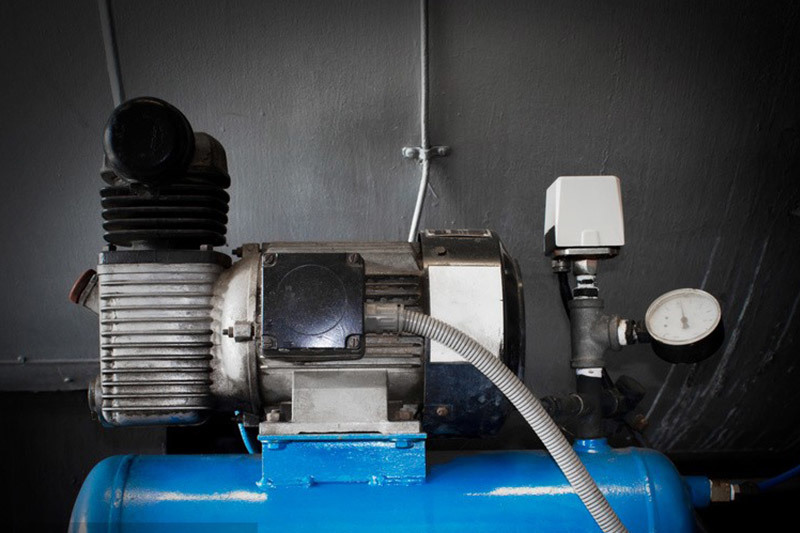

Exploring the Benefits of Integrated Dryer Screw Air Compressors in the Automotive Industry

In the automotive and parts industry, particularly in braking systems, the efficiency and reliability of air compressors are paramount. Integrated dryer screw air compressors are becoming increasingly popular due to their ability to provide high-quality compressed air while also offering integrated drying capabilities. This dual functionality not only optimizes performance but also contributes to

In the automotive and parts industry, particularly in braking systems, the efficiency and reliability of air compressors are paramount. Integrated dryer screw air compressors are becoming increasingly popular due to their ability to provide high-quality compressed air while also offering integrated drying capabilities. This dual functionality not only optimizes performance but also contributes to cost savings over time.

The first noteworthy advantage of integrated dryer screw air compressors is their compact design. By combining both compression and drying processes into a single unit, these compressors occupy less space compared to traditional systems, which require separate components for drying. This is especially beneficial for automotive manufacturers where space can be at a premium. A more compact system also simplifies installation and maintenance, allowing for easier access and reduced downtime.

Moreover, an integrated dryer screw air compressor offers superior air quality. The drying component effectively removes moisture from the compressed air, which is crucial for braking systems. Moisture can lead to corrosion and damage to pneumatic components, significantly affecting their lifespan and reliability. By ensuring that the air delivered is free from moisture, these compressors help maintain the integrity of brake systems, ensuring safer and more reliable vehicle operation.

Another significant benefit is energy efficiency. Integrated dryer screw air compressors are designed to operate with less energy consumption compared to traditional systems. Their advanced technology allows for variable speed drives, which adjust the compressor's output based on the demand for air, thus minimizing energy wastage. In an industry where operational costs are a primary concern, this efficiency translates into significant savings over time.

Additionally, these compressors often come with advanced control systems that monitor performance and provide real-time data. This capability allows automotive professionals to optimize their operations and identify any potential issues before they escalate into major problems. Such proactive maintenance can further enhance the longevity and reliability of braking systems, leading to a more efficient production line.

In summary, the adoption of integrated dryer screw air compressors in the automotive and parts industry, particularly for brake systems, presents numerous advantages. Their compact design, enhanced air quality, energy efficiency, and advanced monitoring capabilities make them a valuable asset for professionals in this field. As the automotive industry continues to evolve, leveraging such technologies will be essential for maintaining competitiveness and ensuring the safety and reliability of vehicles.

The first noteworthy advantage of integrated dryer screw air compressors is their compact design. By combining both compression and drying processes into a single unit, these compressors occupy less space compared to traditional systems, which require separate components for drying. This is especially beneficial for automotive manufacturers where space can be at a premium. A more compact system also simplifies installation and maintenance, allowing for easier access and reduced downtime.

Moreover, an integrated dryer screw air compressor offers superior air quality. The drying component effectively removes moisture from the compressed air, which is crucial for braking systems. Moisture can lead to corrosion and damage to pneumatic components, significantly affecting their lifespan and reliability. By ensuring that the air delivered is free from moisture, these compressors help maintain the integrity of brake systems, ensuring safer and more reliable vehicle operation.

Another significant benefit is energy efficiency. Integrated dryer screw air compressors are designed to operate with less energy consumption compared to traditional systems. Their advanced technology allows for variable speed drives, which adjust the compressor's output based on the demand for air, thus minimizing energy wastage. In an industry where operational costs are a primary concern, this efficiency translates into significant savings over time.

Additionally, these compressors often come with advanced control systems that monitor performance and provide real-time data. This capability allows automotive professionals to optimize their operations and identify any potential issues before they escalate into major problems. Such proactive maintenance can further enhance the longevity and reliability of braking systems, leading to a more efficient production line.

In summary, the adoption of integrated dryer screw air compressors in the automotive and parts industry, particularly for brake systems, presents numerous advantages. Their compact design, enhanced air quality, energy efficiency, and advanced monitoring capabilities make them a valuable asset for professionals in this field. As the automotive industry continues to evolve, leveraging such technologies will be essential for maintaining competitiveness and ensuring the safety and reliability of vehicles.

More news