15 Jul,2025

Why Choose an Integrated Dryer for Your Screw Air Compressor?

Why Choose an Integrated Dryer for Your Screw Air Compressor? In the world of industrial applications, efficiency and reliability are paramount. One critical component that directly influences these factors is the air compressor, particularly the screw air compressor, known for its high performance and reliability. However, the effectiveness of these compressors can be significantly enhanced by in

Why Choose an Integrated Dryer for Your Screw Air Compressor?

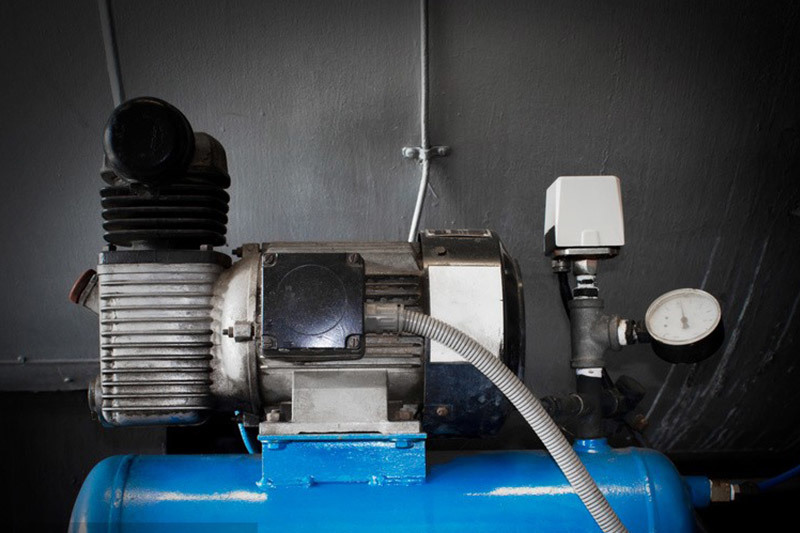

In the world of industrial applications, efficiency and reliability are paramount. One critical component that directly influences these factors is the air compressor, particularly the screw air compressor, known for its high performance and reliability. However, the effectiveness of these compressors can be significantly enhanced by integrating a dryer. In this article, we will delve into the reasons why an integrated dryer is a smart choice for your screw air compressor.

Understanding Screw Air Compressors

Screw air compressors utilize a positive displacement mechanism to compress air. Unlike traditional piston compressors, screw compressors employ two helical screws to compress the air, providing continuous operation and a steady airflow. They are renowned for their durability, efficiency, and low noise levels, making them ideal for a variety of industrial applications.

The Role of Air Dryers in Compressed Air Systems

Air dryers serve a crucial function in compressed air systems. Their primary role is to remove moisture from the compressed air, which can prevent various operational issues down the line. Moisture in compressed air can lead to rust, corrosion, and other detrimental effects on machinery and tools. **Choosing an integrated dryer** with your screw air compressor can mitigate these risks effectively.

Advantages of Using an Integrated Dryer

The integration of a dryer with a screw air compressor offers several notable benefits, which we will explore in detail.

1. Space Efficiency

One of the most significant advantages of an integrated dryer is its compact design. By combining the dryer and compressor into one unit, you save valuable floor space in your facility. This is especially beneficial for businesses with limited operational areas.

2. Cost-Effectiveness

Integrating a dryer with your screw air compressor can lead to substantial cost savings. Separate units often incur additional costs for installation, maintenance, and energy consumption. An integrated system reduces these expenses, as it eliminates the need for additional piping and minimizes the risk of leaks.

3. Simplified Maintenance

Maintaining separate units can be cumbersome and time-consuming. An integrated dryer simplifies maintenance procedures, making it easier for your technicians to monitor and service the system. This dedicated approach can lead to reduced downtime and increased productivity.

4. Enhanced Energy Efficiency

Energy efficiency is a critical factor for any industrial operation. Integrated dryers are designed to work seamlessly with their associated compressors, optimizing energy consumption. By maintaining the ideal temperature and pressure conditions, these systems can significantly reduce energy usage compared to standalone solutions.

5. Improved Air Quality

Moisture-laden air can cause significant damage to pneumatic tools and processes. An integrated dryer ensures that the air supplied to your industrial applications is clean and dry, thereby improving the overall air quality. This not only extends the lifespan of your equipment but also enhances the quality of the products being manufactured.

How Integrated Dryers Work

To appreciate the benefits of integrated dryers, it’s essential to understand how they function within a screw air compressor system.

1. Cooling and Condensation

The first step in the drying process involves cooling the compressed air. An integrated dryer cools the air, which causes moisture to condense. This condensation is then separated from the air stream, reducing humidity levels significantly.

2. Filtration

Following the condensation phase, the air passes through filters that remove any residual moisture and contaminants. This step is critical to ensure that the air delivered to your tools and equipment is free of impurities.

3. Reheating

After filtration, the air is reheated to prevent any condensation from reoccurring in the distribution system. This reheated, dry air is then ready for use in various applications, ensuring optimal performance of your pneumatic tools.

Choosing the Right Integrated Dryer for Your Needs

Selecting the appropriate integrated dryer for your screw air compressor is crucial to maximizing its benefits. Here are some factors to consider:

1. Compressed Air Demand

Assess your facility’s compressed air demand to determine the capacity you need. The integrated dryer should be able to handle peak demands without compromising performance.

2. Operating Environment

Consider the operating conditions where the compressor will be deployed. Environments with high humidity levels may require a more robust integrated dryer capable of handling excess moisture efficiently.

3. Energy Efficiency Ratings

Look for integrated dryers with high energy efficiency ratings. These ratings can provide insight into the operational costs associated with running the dryer, ultimately affecting your bottom line.

4. Maintenance Requirements

Evaluate the maintenance requirements of the integrated dryer. Units that are easier to maintain can save time and reduce the likelihood of unexpected breakdowns.

5. Warranty and Support Options

Lastly, consider the warranty and support options offered by the manufacturer. A reliable warranty can provide peace of mind and protect your investment.

Common Misconceptions About Integrated Dryers

Despite the clear advantages, some misconceptions about integrated dryers persist. Addressing these can help in making an informed decision.

1. Integrated Dryers are Always More Expensive

While the initial investment may seem higher, the long-term savings in maintenance and energy costs make integrated dryers a cost-effective choice.

2. They Require More Complex Installation

In reality, integrated dryers are often simpler to install than standalone units, as they come pre-assembled with the compressor, reducing complexity and installation time.

3. They Have Limited Performance Capabilities

Modern integrated dryers are designed to handle a wide range of applications, providing performance that can meet or exceed that of standalone options.

FAQs

1. What is the lifespan of an integrated dryer?

The lifespan of an integrated dryer can vary, but with proper maintenance, they typically last between 10 to 15 years.

2. How do I know if my air is dry enough?

Using a dew point meter can help determine the dryness of your compressed air. Aim for a dew point of at least 3 to 10 degrees Fahrenheit below the lowest temperature in your application.

3. Can I retro-fit a dryer to my existing compressor?

Yes, most air compressors can be retrofitted with a separate dryer. However, integrating a new system is often more efficient.

4. What maintenance do integrated dryers require?

Regular checks of the filtration system, condensate drains, and overall system performance are essential. Routine maintenance can help prevent costly downtimes.

5. Are integrated dryers suitable for all industries?

Integrated dryers are versatile and can be used across various industries, including manufacturing, automotive, and food processing, where dry air is critical.

Conclusion

Choosing an integrated dryer for your screw air compressor is a strategic decision that can lead to substantial benefits. From improved energy efficiency and maintenance simplicity to enhanced air quality, the advantages are compelling. By integrating these systems, businesses not only save on costs but also extend the lifespan of their equipment, ultimately driving productivity and profitability. As you evaluate your options, consider the specific needs of your operations to select the ideal integrated dryer that aligns with your goals.

More news