28 Sep,2025

Unlocking Efficiency: The Benefits of Integrated Dryer Screw Air Compressors in Automotive Systems

When it comes to the automotive and parts industry, particularly in braking systems, the choice of air compressor can significantly impact performance and reliability. One innovative solution that stands out is the integrated dryer screw air compressor. This technology not only compresses air but also integrates a drying mechanism, ensuring that the air delivered is free from moisture, which is cr

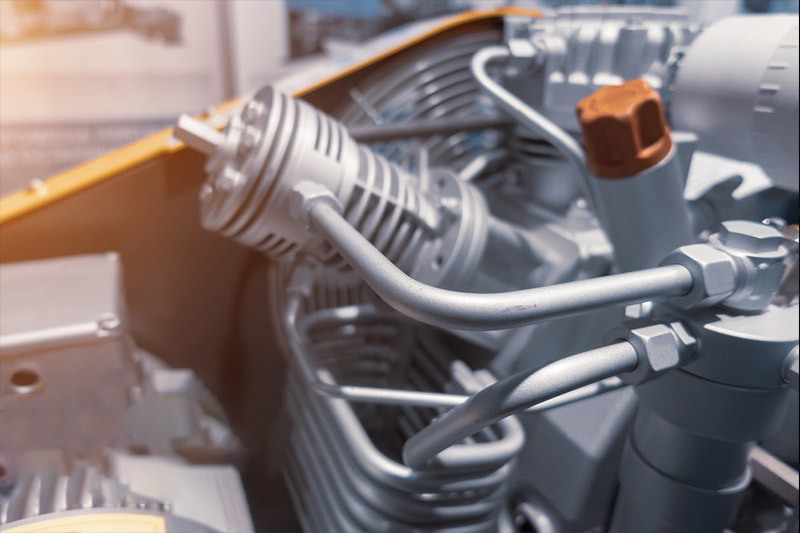

When it comes to the automotive and parts industry, particularly in braking systems, the choice of air compressor can significantly impact performance and reliability. One innovative solution that stands out is the integrated dryer screw air compressor. This technology not only compresses air but also integrates a drying mechanism, ensuring that the air delivered is free from moisture, which is crucial for the optimal functioning of pneumatic systems.

One of the primary benefits of integrated dryer screw air compressors is their ability to enhance the overall efficiency of pneumatic tools and systems. Traditional air compressors often require separate drying units, which can lead to increased energy consumption and additional maintenance. By incorporating the drying process directly into the compressor, these integrated systems reduce energy losses and provide a more consistent output of dry air. This efficiency is particularly important in brake systems, where moisture can compromise performance by causing corrosion and reducing the effectiveness of pneumatic actuators.

Moreover, integrated dryer screw air compressors are designed for durability and reliability. The rugged construction and advanced engineering of these compressors ensure that they can withstand the demanding conditions typically found in automotive environments. This reliability translates into less downtime and lower maintenance costs, making them a more economically viable option for businesses in the automotive sector.

Another aspect to consider is the reduction of footprint in operational facilities. With a traditional setup, having separate compressors and dryers can take up considerable space. Integrated systems streamline the setup, allowing businesses to save valuable real estate in their workshops or production facilities. This compact nature is particularly beneficial for smaller operations or those looking to optimize their workspace.

Integrated dryer screw air compressors also come with advanced control systems that allow users to monitor and adjust operating parameters easily. These features enable operators to optimize performance based on specific applications, ensuring that the air delivered meets the precise requirements of various automotive systems. This versatility not only enhances the functionality of equipment but also contributes to the overall productivity of operations.

In conclusion, the integrated dryer screw air compressor represents a pivotal advancement in air compression technology for the automotive industry, especially in brake systems. Its benefits—ranging from enhanced efficiency and reliability to space-saving designs—make it an appealing choice for businesses looking to improve their operations. By investing in this technology, automotive professionals can ensure that their systems are running at peak performance while minimizing long-term costs and maintenance needs.

One of the primary benefits of integrated dryer screw air compressors is their ability to enhance the overall efficiency of pneumatic tools and systems. Traditional air compressors often require separate drying units, which can lead to increased energy consumption and additional maintenance. By incorporating the drying process directly into the compressor, these integrated systems reduce energy losses and provide a more consistent output of dry air. This efficiency is particularly important in brake systems, where moisture can compromise performance by causing corrosion and reducing the effectiveness of pneumatic actuators.

Moreover, integrated dryer screw air compressors are designed for durability and reliability. The rugged construction and advanced engineering of these compressors ensure that they can withstand the demanding conditions typically found in automotive environments. This reliability translates into less downtime and lower maintenance costs, making them a more economically viable option for businesses in the automotive sector.

Another aspect to consider is the reduction of footprint in operational facilities. With a traditional setup, having separate compressors and dryers can take up considerable space. Integrated systems streamline the setup, allowing businesses to save valuable real estate in their workshops or production facilities. This compact nature is particularly beneficial for smaller operations or those looking to optimize their workspace.

Integrated dryer screw air compressors also come with advanced control systems that allow users to monitor and adjust operating parameters easily. These features enable operators to optimize performance based on specific applications, ensuring that the air delivered meets the precise requirements of various automotive systems. This versatility not only enhances the functionality of equipment but also contributes to the overall productivity of operations.

In conclusion, the integrated dryer screw air compressor represents a pivotal advancement in air compression technology for the automotive industry, especially in brake systems. Its benefits—ranging from enhanced efficiency and reliability to space-saving designs—make it an appealing choice for businesses looking to improve their operations. By investing in this technology, automotive professionals can ensure that their systems are running at peak performance while minimizing long-term costs and maintenance needs.

More news