26 Nov,2025

Understanding Integrated Dryer Screw Air Compressors: A Key Component in Automotive Brake Systems

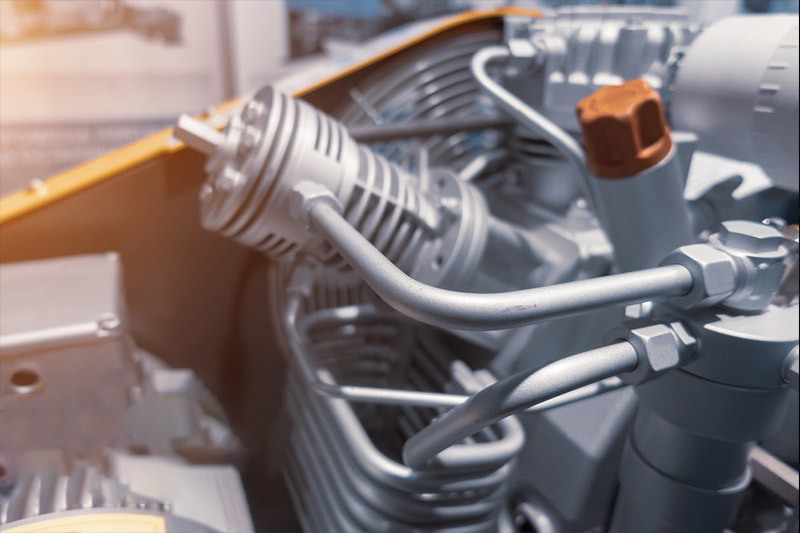

Integrated dryer screw air compressors represent a technological advancement in the automotive and parts industry, particularly in the context of braking systems. These compressors combine the functions of air compression and drying into a single unit, offering numerous benefits over traditional systems. Understanding their mechanics and advantages can empower professionals in the automotive secto

Integrated dryer screw air compressors represent a technological advancement in the automotive and parts industry, particularly in the context of braking systems. These compressors combine the functions of air compression and drying into a single unit, offering numerous benefits over traditional systems. Understanding their mechanics and advantages can empower professionals in the automotive sector to make informed decisions regarding their applications.

At the core of an integrated dryer screw air compressor lies the screw compression mechanism. This design utilizes two interlocking rotors to compress air without the need for excessive heat generation, thereby improving energy efficiency. The integration of a drying unit within the compressor means that moisture-laden air is treated immediately after compression, minimizing the risks of corrosion and ice formation in pneumatic systems. This is particularly critical in braking systems, where the reliability of air supply is paramount for safety and performance.

One of the primary advantages of using an integrated dryer screw air compressor is its compact design. By combining two components into one unit, it reduces the overall footprint required for installation, making it easier to integrate into existing systems. This is particularly beneficial in automotive applications where space can be limited. Furthermore, the reduced number of components can lead to lower maintenance requirements and costs, as there are fewer parts that can fail or require service.

In addition to the compact design, these compressors also offer enhanced energy efficiency. The screw compression process is inherently more efficient than traditional piston compressors, leading to lower energy consumption. This not only translates to cost savings for businesses but also aligns with the growing emphasis on sustainability within the automotive industry. Efficient operation reduces the carbon footprint of manufacturing and maintenance processes, contributing to a greener future.

Moreover, integrated dryer screw air compressors provide consistent air quality, ensuring that the air used in pneumatic systems remains dry and clean. This is essential for the optimal functioning of braking systems, where any moisture or contaminants can lead to performance issues or even system failures. By maintaining the integrity of the air supply, these compressors enhance the overall reliability of the braking system, thereby improving safety for drivers and passengers alike.

In conclusion, integrated dryer screw air compressors play a vital role in the automotive and parts industry, particularly in the realm of braking systems. Their innovative design not only streamlines system integration but also enhances energy efficiency and air quality. For professionals in the automotive sector, understanding the benefits and functionalities of these compressors is crucial in making informed decisions that can lead to improved performance and safety in their applications. Embracing advancements such as these can pave the way for a more reliable and efficient automotive future.

At the core of an integrated dryer screw air compressor lies the screw compression mechanism. This design utilizes two interlocking rotors to compress air without the need for excessive heat generation, thereby improving energy efficiency. The integration of a drying unit within the compressor means that moisture-laden air is treated immediately after compression, minimizing the risks of corrosion and ice formation in pneumatic systems. This is particularly critical in braking systems, where the reliability of air supply is paramount for safety and performance.

One of the primary advantages of using an integrated dryer screw air compressor is its compact design. By combining two components into one unit, it reduces the overall footprint required for installation, making it easier to integrate into existing systems. This is particularly beneficial in automotive applications where space can be limited. Furthermore, the reduced number of components can lead to lower maintenance requirements and costs, as there are fewer parts that can fail or require service.

In addition to the compact design, these compressors also offer enhanced energy efficiency. The screw compression process is inherently more efficient than traditional piston compressors, leading to lower energy consumption. This not only translates to cost savings for businesses but also aligns with the growing emphasis on sustainability within the automotive industry. Efficient operation reduces the carbon footprint of manufacturing and maintenance processes, contributing to a greener future.

Moreover, integrated dryer screw air compressors provide consistent air quality, ensuring that the air used in pneumatic systems remains dry and clean. This is essential for the optimal functioning of braking systems, where any moisture or contaminants can lead to performance issues or even system failures. By maintaining the integrity of the air supply, these compressors enhance the overall reliability of the braking system, thereby improving safety for drivers and passengers alike.

In conclusion, integrated dryer screw air compressors play a vital role in the automotive and parts industry, particularly in the realm of braking systems. Their innovative design not only streamlines system integration but also enhances energy efficiency and air quality. For professionals in the automotive sector, understanding the benefits and functionalities of these compressors is crucial in making informed decisions that can lead to improved performance and safety in their applications. Embracing advancements such as these can pave the way for a more reliable and efficient automotive future.

More news