11 Dec,2025

Integrated Dryer vs. Traditional Compressors: Which is Right for You?

Integrated Dryer vs. Traditional Compressors: Which is Right for You? Table of Contents 1. Understanding the Basics of Air Compressors 2. What is an Integrated Dryer? 3. What are Traditional Compressors? 4. Key Differences Between Integrated Dryers and Traditional Compressors 4.1. Efficiency and Performance 4.2. Space and Installation Considerations 4.3. Maintenance Requirements 4.4. Cost Analysis

Integrated Dryer vs. Traditional Compressors: Which is Right for You?

Table of Contents

1. Understanding the Basics of Air Compressors

2. What is an Integrated Dryer?

3. What are Traditional Compressors?

4. Key Differences Between Integrated Dryers and Traditional Compressors

4.1. Efficiency and Performance

4.2. Space and Installation Considerations

4.3. Maintenance Requirements

4.4. Cost Analysis

5. Pros and Cons of Integrated Dryers

6. Pros and Cons of Traditional Compressors

7. Ideal Applications for Integrated Dryers

8. Ideal Applications for Traditional Compressors

9. Frequently Asked Questions

9.1. What are the benefits of using an integrated dryer?

9.2. How do I choose between an integrated dryer and a traditional compressor?

9.3. Can I retrofit an integrated dryer to an existing compressor?

9.4. What maintenance do integrated dryers require?

9.5. Are traditional compressors more reliable than integrated systems?

10. Conclusion

1. Understanding the Basics of Air Compressors

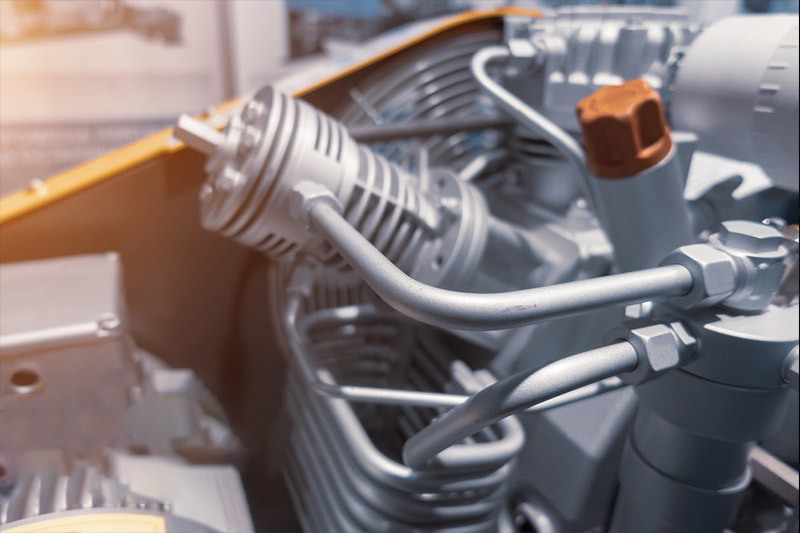

Air compressors are essential tools in various industries, providing a source of compressed air for numerous applications. They convert power into potential energy stored in pressurized air, which can then be used to power pneumatic tools, inflate tires, or operate machinery. Understanding the different types of air compressors, particularly integrated dryers and traditional compressors, is crucial for making informed equipment choices.

2. What is an Integrated Dryer?

An **integrated dryer** is a compact system that combines air compression and moisture removal in one unit. This configuration is designed to deliver dry, compressed air directly to equipment without the need for additional components. Integrated dryers can be either refrigerated or desiccant types, each tailored to specific applications and environments.

Refrigerated integrated dryers cool incoming compressed air to condense moisture, allowing water to be drained away automatically. Desiccant dryers, on the other hand, utilize moisture-absorbing materials to remove humidity from the air stream. The benefits of integrated dryers include reduced space requirements, simplified installation, and improved efficiency.

3. What are Traditional Compressors?

**Traditional compressors** are standalone systems that primarily focus on compressing air. They can be powered by electricity or gas and come in various configurations, such as rotary screw, reciprocating, and centrifugal designs. Unlike integrated dryers, traditional compressors typically require external drying systems to manage moisture content in the compressed air, leading to potential inefficiencies and increased maintenance needs.

While traditional compressors can be more versatile in terms of capacity and power, the added complexity of managing moisture often necessitates additional components, such as filters and dryers, making them larger and potentially more cumbersome to install.

4. Key Differences Between Integrated Dryers and Traditional Compressors

Understanding the distinct features of integrated dryers and traditional compressors is essential for selecting the right equipment for your needs.

4.1. Efficiency and Performance

Integrated dryers enhance efficiency by providing dry air directly from the compressor, reducing energy losses associated with moisture. This feature is particularly beneficial in applications where air quality is critical. In contrast, traditional compressors may struggle with moisture management if not paired with appropriate drying solutions.

4.2. Space and Installation Considerations

The compact nature of integrated dryers makes them ideal for facilities with limited space. They can be easily installed in tight areas, whereas traditional compressors often require more room for the compressor unit and any associated drying systems. This distinction can significantly impact your facility's layout and operational flow.

4.3. Maintenance Requirements

Maintenance is a crucial factor to consider when choosing between these two systems. Integrated dryers generally have lower maintenance needs due to fewer components. Traditional compressors, however, may require regular inspection and servicing of separate drying systems to ensure optimal performance.

4.4. Cost Analysis

When evaluating costs, it's essential to consider both initial investment and long-term operational expenses. Integrated dryers may have a higher upfront cost but can lead to significant savings over time through reduced energy consumption and lower maintenance costs. Traditional compressors, while potentially cheaper initially, may incur higher costs for auxiliary drying equipment and increased maintenance.

5. Pros and Cons of Integrated Dryers

**Pros:**

- Compact design saves valuable space.

- Provides dry air directly from the compressor.

- Reduced energy losses due to efficient moisture management.

- Lower maintenance requirements.

**Cons:**

- Potentially higher initial costs.

- Limited to specific applications based on dryer type (refrigerated vs. desiccant).

6. Pros and Cons of Traditional Compressors

**Pros:**

- Versatile options available for various capacities and power sources.

- Can be tailored for diverse applications and environments.

**Cons:**

- Requires additional components for moisture removal.

- Larger footprint and more complex installation.

- Higher maintenance needs can lead to increased downtime.

7. Ideal Applications for Integrated Dryers

Integrated dryers are particularly suited for applications that require high-quality, dry air. Industries such as pharmaceuticals, food and beverage, and electronics manufacturing benefit significantly from integrated systems. These environments demand strict control over moisture levels to prevent product contamination and maintain quality standards.

8. Ideal Applications for Traditional Compressors

Traditional compressors can be advantageous in settings where air quality is less critical or where high-volume air delivery is necessary. Construction sites, automotive repair shops, and general manufacturing facilities often utilize traditional compressors due to their versatility and capacity options.

9. Frequently Asked Questions

9.1. What are the benefits of using an integrated dryer?

Integrated dryers deliver consistently dry air, reducing the risk of moisture-related issues in your operations. They also save space and lower maintenance costs, making them an efficient choice for many applications.

9.2. How do I choose between an integrated dryer and a traditional compressor?

Consider your specific application needs, available space, and budget. If moisture management is crucial, an integrated dryer may be more suitable. For diverse applications requiring higher air delivery volumes, a traditional compressor could be the better option.

9.3. Can I retrofit an integrated dryer to an existing compressor?

Yes, retrofitting an integrated dryer to an existing compressor is possible, but it depends on the specific equipment. Consult a professional to ensure compatibility and optimal performance.

9.4. What maintenance do integrated dryers require?

Integrated dryers typically require less maintenance than traditional systems. Regular checks of filters and moisture traps, along with occasional servicing, should suffice to maintain optimal performance.

9.5. Are traditional compressors more reliable than integrated systems?

Reliability can vary based on application and maintenance. Traditional compressors may require more attention to moisture management, which can impact reliability. Properly maintained integrated dryers often provide consistent performance.

10. Conclusion

Choosing between integrated dryers and traditional compressors ultimately depends on your specific operational needs, space constraints, and budget considerations. Integrated dryers offer convenience, efficiency, and lower maintenance, making them ideal for environments requiring dry air. Traditional compressors, while versatile and powerful, necessitate additional components for effective moisture management. By carefully evaluating your requirements, we can help you make an informed decision that enhances your facility’s performance and longevity.

More news