29 Nov,2025

Revolutionizing Pharmaceutical Production: Innovations in Air Compressor Technology

Revolutionizing Pharmaceutical Production: Innovations in Air Compressor Technology Table of Contents Introduction to Air Compressor Technology in Pharmaceuticals Understanding the Importance of Air Compressors in the Pharmaceutical Industry Recent Innovations in Air Compressor Technology Energy-Efficient Compressors Smart Compressor Systems

Revolutionizing Pharmaceutical Production: Innovations in Air Compressor Technology

Table of Contents

- Introduction to Air Compressor Technology in Pharmaceuticals

- Understanding the Importance of Air Compressors in the Pharmaceutical Industry

- Recent Innovations in Air Compressor Technology

- The Role of Compressed Air Quality in Pharmaceuticals

- Regulatory Compliance and Air Compressor Standards

- Case Studies: Successful Implementations of Innovative Air Compressors

- Future Trends in Air Compressor Technology for Pharmaceuticals

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Air Compressor Technology in Pharmaceuticals

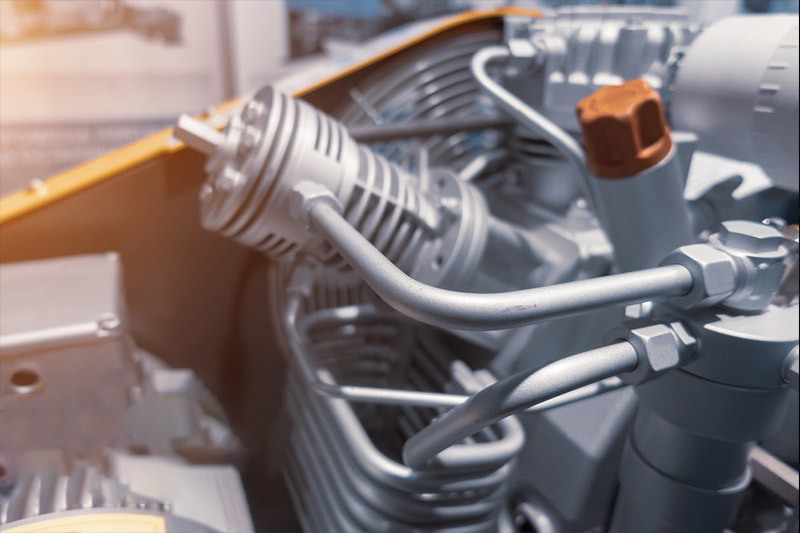

The pharmaceutical industry is known for its rigorous standards and stringent regulatory requirements. In this high-stakes environment, the role of **air compressors** is often understated, yet they are vital for various applications, from powering machinery to providing critical clean air for production processes. This article delves into the latest innovations in air compressor technology, specifically tailored for the pharmaceutical sector, illustrating how these advancements contribute to improved efficiency and compliance.

Understanding the Importance of Air Compressors in the Pharmaceutical Industry

Air compressors serve as the backbone of many operations within pharmaceutical manufacturing. They provide the necessary power for pneumatic tools, operate various machinery, and ensure the delivery of clean, dry air for processes such as mixing, packaging, and conveying. Furthermore, the quality of compressed air can significantly influence product quality, making it imperative to adopt advanced compressor technologies.

The Diverse Applications of Air Compressors

Air compressors are used in numerous applications within the pharmaceutical sector, including:

- **Pneumatic conveying systems** for transporting powders and granules.

- **Mixing processes** where precise control of air pressure is crucial.

- **Packaging lines** that require consistent air supply for sealing and operation.

Understanding these applications highlights the need for continuous improvement and innovation in air compressor technology.

Recent Innovations in Air Compressor Technology

The air compressor landscape is evolving, driven by technological advancements and increasing demands for efficiency and sustainability. Key innovations include:

Energy-Efficient Compressors

Energy consumption is a significant concern for pharmaceutical manufacturers. Innovations in **energy-efficient compressors** have led to designs that reduce energy usage while maintaining high performance. Features such as variable speed drives (VSD) allow compressors to adjust their speed based on real-time demand, leading to substantial energy savings.

Smart Compressor Systems

The integration of the Internet of Things (IoT) into air compressor systems has given rise to **smart compressors**. These systems can monitor performance metrics, predict maintenance needs, and optimize operations through real-time data analysis. By utilizing advanced algorithms, smart compressors can enhance operational efficiency and minimize downtime, ensuring continuous production.

Noise Reduction Technologies

Noise pollution is a growing concern in pharmaceutical production environments. Recent innovations focus on reducing noise levels emitted by air compressors. Technologies such as **acoustic enclosures** and advanced soundproofing materials have been developed to create quieter operating environments, improving workplace conditions for employees.

The Role of Compressed Air Quality in Pharmaceuticals

Compressed air quality directly impacts the quality and safety of pharmaceutical products. Contaminants such as moisture, oil, and particulate matter can compromise product integrity. Innovations in air compressor technology include advanced filtration and drying systems designed to produce clean, dry air that meets stringent industry standards.

Importance of Drying Systems

Moisture can lead to microbial growth and product degradation. Advanced **desiccant dryers** and refrigeration dryers are now integral components of modern air compressor systems, ensuring that the compressed air used in production is free from moisture.

Regulatory Compliance and Air Compressor Standards

Compliance with regulatory standards is non-negotiable in the pharmaceutical industry. The **FDA** and other regulatory bodies impose strict guidelines on the quality of compressed air used in manufacturing processes. Advanced air compressor technologies are designed to meet or exceed these regulations, ensuring that pharmaceutical companies maintain compliance while delivering high-quality products.

Case Studies: Successful Implementations of Innovative Air Compressors

Several pharmaceutical companies have successfully implemented innovative air compressor technologies, resulting in improved operational efficiency and product quality.

Case Study 1: Company A

Company A adopted energy-efficient compressors equipped with VSD technology, leading to a **30% reduction in energy costs**. Additionally, the integration of smart compressor systems enabled predictive maintenance, decreasing downtime significantly.

Case Study 2: Company B

Company B focused on improving air quality by investing in advanced filtration systems. This upgrade not only ensured compliance with regulatory standards but also enhanced product stability, resulting in increased customer satisfaction.

Future Trends in Air Compressor Technology for Pharmaceuticals

The future of air compressor technology in the pharmaceutical sector looks promising, with several trends poised to shape the industry. Emphasis on sustainability will continue to drive innovations aimed at reducing energy consumption and environmental impact. Furthermore, the integration of artificial intelligence (AI) in compressor operation and maintenance holds the potential for even greater efficiency gains.

Frequently Asked Questions (FAQs)

1. What are the main benefits of using energy-efficient air compressors in pharmaceuticals?

Energy-efficient air compressors help reduce operational costs, minimize carbon footprints, and enhance overall system performance.

2. How does air quality affect pharmaceutical manufacturing processes?

Poor air quality can introduce contaminants that compromise product integrity and safety, making it essential to maintain high standards of compressed air quality.

3. What regulatory standards should pharmaceutical companies consider regarding air compressors?

Pharmaceutical companies must adhere to standards set by regulatory bodies such as the FDA, which outline requirements for the quality of compressed air used in manufacturing.

4. How can smart compressor systems improve operational efficiency?

Smart compressor systems leverage real-time data to optimize performance, predict maintenance needs, and reduce downtime, thereby enhancing operational efficiency.

5. What future innovations can we expect in air compressor technology?

Future innovations may include further advancements in energy efficiency, the integration of AI for predictive analytics, and enhanced noise reduction technologies.

Conclusion

The advancements in air compressor technology for the pharmaceutical sector are redefining operational capabilities and setting new standards for quality and efficiency. By embracing innovations such as energy-efficient systems, smart technologies, and rigorous air quality measures, pharmaceutical companies can significantly enhance their production processes, ensuring compliance and improving product quality. As the industry continues to evolve, staying ahead of these innovations will be crucial for maintaining a competitive edge in the pharmaceutical market.

More news