07 Jan,2026

The Science Behind Rodi Piston Air Compressors: An In-Depth Exploration of Their Functionality

The Science Behind Rodi Piston Air Compressors: How They Work Table of Contents 1. Introduction to Rodi Piston Air Compressors 2. What is a Piston Air Compressor? 3. How Does a Piston Air Compressor Work? 3.1 Key Components of Rodi Piston Air Compressors 3.2 The Compression Cycle Explained 4. Applications of Rodi Piston Air Compressors

The Science Behind Rodi Piston Air Compressors: How They Work

Table of Contents

- 1. Introduction to Rodi Piston Air Compressors

- 2. What is a Piston Air Compressor?

- 3. How Does a Piston Air Compressor Work?

- 4. Applications of Rodi Piston Air Compressors

- 5. Benefits of Using Rodi Piston Air Compressors

- 6. Maintenance Tips for Longevity

- 7. Common Issues and Troubleshooting

- 8. Conclusion

- 9. FAQs About Rodi Piston Air Compressors

1. Introduction to Rodi Piston Air Compressors

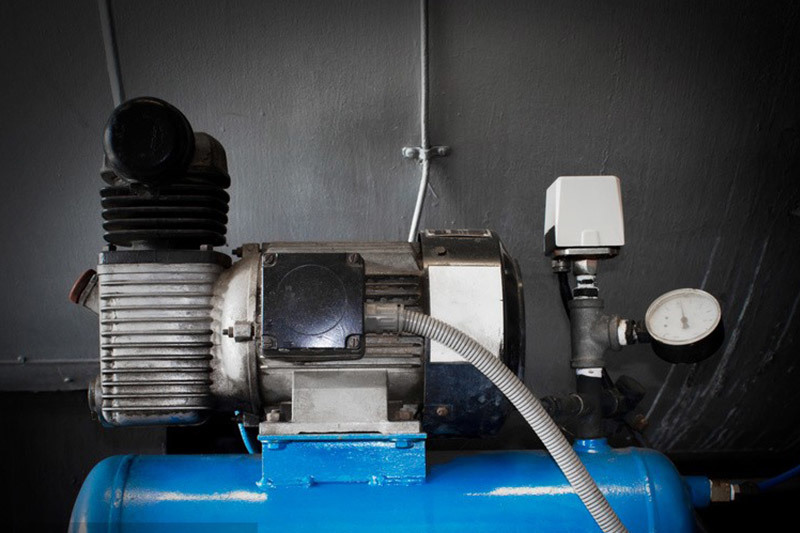

Rodi piston air compressors are essential tools in various industrial and commercial applications. These compressors utilize a piston-driven mechanism to convert power into potential energy, stored as compressed air. The efficiency and effectiveness of Rodi air compressors make them popular for tasks ranging from powering pneumatic tools to inflating tires. Understanding how these machines operate not only enhances their utilization but also allows users to make informed choices when selecting and maintaining their equipment.

2. What is a Piston Air Compressor?

A piston air compressor is a type of positive displacement compressor that compresses air using a piston mechanism. This design is notable for its ability to generate high pressures, making it suitable for several applications that require consistent airflow and pressure. Piston air compressors can be categorized into two main types: single-stage and two-stage compressors, which differ in their efficiency and output capabilities.

2.1 Single-Stage vs. Two-Stage Compressors

Single-stage compressors compress air in one cycle, making them ideal for lower pressure applications. In contrast, two-stage compressors involve a two-step process that allows for higher pressure outputs, making them suitable for more demanding tasks. The choice between these two types depends on the specific requirements of the tasks at hand.

3. How Does a Piston Air Compressor Work?

The operation of a Rodi piston air compressor is based on a straightforward yet highly effective principle. The compressor draws in air and compresses it to increase its pressure, making it available for various applications. The process involves several critical components and cycles, which we will explore in detail.

3.1 Key Components of Rodi Piston Air Compressors

Several key components work together to ensure the effective operation of Rodi piston air compressors. These include:

- **Piston and Cylinder**: The heart of the compressor, where the actual compression occurs.

- **Crankshaft**: Converts rotational motion into linear motion to drive the piston.

- **Valves**: Control the intake and exhaust of air, ensuring a smooth cycle.

- **Flywheel**: Helps maintain consistent operation and reduces wear on the motor.

- **Air Tank**: Stores the compressed air until needed for use.

- **Pressure Switch**: Regulates the compressor’s operation based on the air pressure in the tank.

3.2 The Compression Cycle Explained

The compression cycle in a piston air compressor can be broken down into four main stages:

1. **Intake**: The piston moves downward, creating a vacuum that draws in air through the intake valve.

2. **Compression**: As the piston moves upward, the intake valve closes, and the air is compressed in the cylinder.

3. **Discharge**: When the pressure reaches a certain level, the discharge valve opens, and the compressed air is released into the storage tank.

4. **Repeat**: The cycle continues as the piston moves back down to draw in more air.

This efficient cycle allows Rodi piston air compressors to deliver a continuous supply of compressed air, making them highly effective for various applications.

4. Applications of Rodi Piston Air Compressors

Rodi piston air compressors are versatile machines used across many industries. Their applications include:

- **Automotive Repair**: Powering pneumatic tools such as impact wrenches and air ratchets.

- **Manufacturing**: Assisting in assembly lines and operating machinery.

- **Construction**: Supplying air for pneumatic nail guns and tools.

- **HVAC Systems**: Used in refrigeration applications and maintaining air conditioning units.

- **DIY Projects**: Useful for tasks such as painting, inflating tires, and operating various handheld tools.

5. Benefits of Using Rodi Piston Air Compressors

Choosing Rodi piston air compressors comes with numerous benefits:

- **High Efficiency**: Designed to deliver significant air pressure, making them effective for heavy-duty tasks.

- **Durability**: Built with robust materials that withstand extensive use, ensuring a long lifespan.

- **Versatility**: Suitable for a wide range of applications across multiple industries.

- **Cost-Effective**: Provides reliable performance, reducing downtime and maintenance costs over time.

- **Compact Design**: Many models are designed to save space without compromising functionality.

6. Maintenance Tips for Longevity

To ensure your Rodi piston air compressor operates efficiently and lasts longer, regular maintenance is key. Here are some essential tips:

- **Regularly Change the Oil**: For oil-lubricated models, ensure oil is changed regularly to prevent wear and tear.

- **Check the Air Filter**: Clean or replace the air filter as needed to maintain airflow efficiency.

- **Inspect Hoses and Fittings**: Look for cracks or leaks to prevent air loss and ensure optimal performance.

- **Drain the Tank**: Regularly drain water buildup in the tank to prevent rust and maintain air quality.

- **Monitor Pressure Levels**: Keep an eye on the pressure switch and ensure it operates within the manufacturer’s recommended range.

7. Common Issues and Troubleshooting

Even the best air compressors can face issues. Here are some common problems and how to troubleshoot them:

- **Compressor Won't Start**: Check the power supply and ensure all switches are functioning correctly.

- **Insufficient Pressure**: Inspect for leaks in hoses or fittings and ensure the intake filter is clean.

- **Overheating**: Ensure that the compressor has adequate ventilation and that the oil levels are sufficient.

- **Unusual Noises**: Listen for rattling or grinding sounds, indicative of mechanical issues that may require professional repair.

8. Conclusion

Rodi piston air compressors play a crucial role in numerous industrial and commercial applications. Their design, based on a simple yet effective piston mechanism, allows for high-pressure air generation that is essential for various tasks. By understanding how these machines work, their applications, and maintenance needs, users can maximize their performance and longevity. Investing in a quality Rodi piston air compressor means investing in efficiency, reliability, and versatility in your operations.

9. FAQs About Rodi Piston Air Compressors

1. What is the difference between single-stage and two-stage piston air compressors?

Single-stage compressors compress air in one cycle and are suitable for lower pressure requirements, while two-stage compressors provide higher pressures suitable for more demanding applications.

2. How often should I perform maintenance on my Rodi piston air compressor?

Regular maintenance should be performed every few months, depending on usage. Key tasks include checking oil levels, cleaning filters, and inspecting for leaks.

3. Can I use my Rodi piston air compressor for painting?

Yes, many users utilize piston air compressors for painting tasks due to their ability to deliver consistent airflow and pressure.

4. What is the average lifespan of a Rodi piston air compressor?

With proper maintenance, Rodi piston air compressors can last anywhere from 10 to 20 years.

5. What should I do if my compressor is not generating enough pressure?

Check for leaks in hoses, ensure the air filter is clean, and verify that the pressure switch is functioning correctly.

By exploring the science behind Rodi piston air compressors, we gain a deeper appreciation of their significance in various industries. With their robust design and efficient operation, these compressors remain top choices for professionals and DIY enthusiasts alike.

More news