01 Oct,2025

Choosing the Right Air Compressor for Your Pharmaceutical Operations: A Comprehensive Guide

Choosing the Right Air Compressor for Your Pharmaceutical Operations Table of Contents Understanding the Role of Air Compressors in Pharmaceutical Operations Types of Air Compressors and Their Applications in Pharmaceuticals Key Factors in Selecting an Air Compressor Compressor Specifications to Consider for Pharmaceuticals Compliance and Regulatory Requirements in the Pharmac

Choosing the Right Air Compressor for Your Pharmaceutical Operations

Table of Contents

- Understanding the Role of Air Compressors in Pharmaceutical Operations

- Types of Air Compressors and Their Applications in Pharmaceuticals

- Key Factors in Selecting an Air Compressor

- Compressor Specifications to Consider for Pharmaceuticals

- Compliance and Regulatory Requirements in the Pharmaceutical Industry

- Maintenance Best Practices for Air Compressors

- Common Mistakes to Avoid When Choosing an Air Compressor

- Future Trends in Air Compressor Technology and Their Impact

- Frequently Asked Questions

- Conclusion

Understanding the Role of Air Compressors in Pharmaceutical Operations

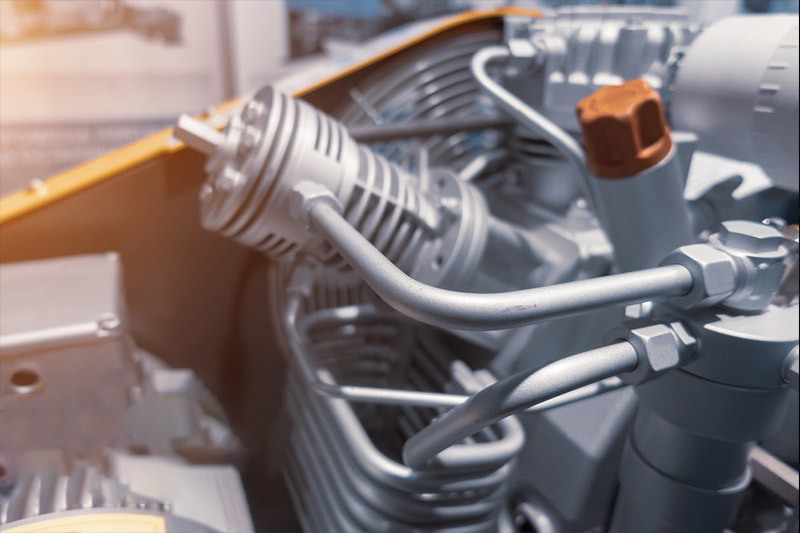

Air compressors play a pivotal role in pharmaceutical manufacturing processes. They are essential for powering tools, delivering pressurized air for various applications, and ensuring the proper functioning of equipment. In an industry where precision, cleanliness, and efficiency are paramount, selecting the right air compressor can significantly impact operational success.

In pharmaceutical operations, air compressors are used for:

- **Packaging**: Ensuring that products are sealed correctly to maintain sterility.

- **Material Handling**: Assisting in the transfer of materials within the facility.

- **Cleaning**: Providing clean, dry air for the cleaning of equipment and workspaces.

- **Actuation**: Powering pneumatic systems and machinery.

By understanding these roles, companies can make informed decisions about the types of compressors that best suit their needs.

Types of Air Compressors and Their Applications in Pharmaceuticals

When it comes to air compressors, there are several types available, each with unique applications in the pharmaceutical industry.

Reciprocating Air Compressors

Reciprocating air compressors are known for their high efficiency and are suitable for applications requiring high pressure. They are commonly used for intermittent operations and can deliver oil-free air, making them ideal for applications where air quality is critical.

Rotary Screw Compressors

Rotary screw compressors are favored for their continuous operation and higher air delivery capabilities. They provide a steady supply of compressed air, which is essential for processes that require a constant flow, such as in the production line.

Scroll Compressors

Scroll compressors are compact and efficient, making them suitable for smaller pharmaceutical operations. They are known for their quiet operation and minimal maintenance requirements, offering a reliable source of clean air.

Oil-Free Air Compressors

Oil-free air compressors are crucial in environments where contamination from oil must be avoided. These compressors utilize advanced technologies to produce clean air, making them ideal for sensitive pharmaceutical operations.

Key Factors in Selecting an Air Compressor

Selecting the right air compressor for pharmaceutical operations involves several critical factors:

Air Quality Requirements

The pharmaceutical industry has stringent air quality standards. Understanding the required cleanliness levels is essential in selecting an appropriate compressor. Oil-free compressors are often recommended to avoid contamination.

Capacity and Pressure Needs

Evaluate the air demand of your operations. Calculate the required flow rate and pressure to ensure the selected compressor meets your specific needs without underperforming or overloading.

Energy Efficiency

Energy costs can significantly impact operational expenses. Opting for energy-efficient models can lead to substantial savings over time, making this a vital consideration in the selection process.

Size and Footprint

Consider the available space in your facility. Compressors come in various sizes, and selecting one that fits within your operational footprint is crucial for optimizing space and workflow.

Compressor Specifications to Consider for Pharmaceuticals

When examining potential air compressors, pay attention to the following specifications:

Compressor Type

Assess whether a reciprocating, rotary screw, or scroll compressor is best suited for your needs based on the operational requirements discussed earlier.

Flow Rate and Pressure Rating

Ensure that the compressor can deliver the necessary flow rate and pressure required for your operations, typically measured in cubic feet per minute (CFM) and pounds per square inch (PSI).

Noise Levels

In sensitive environments, noise levels can be a concern. Choose a compressor with acceptable noise ratings to maintain a conducive work environment.

Durability and Reliability

Look for compressors built with high-quality components that are designed for long-term reliability, reducing downtime and maintenance costs.

Compliance and Regulatory Requirements in the Pharmaceutical Industry

Pharmaceutical operations are subject to strict regulatory standards imposed by organizations such as the FDA and EMA. Compliance with these regulations is crucial for maintaining product safety and efficacy.

GMP Compliance

Good Manufacturing Practices (GMP) dictate that air compressors must produce air that meets specific cleanliness and quality standards. Ensure your chosen compressor is compliant with these regulations.

Validation Requirements

Validation of your air compressor system is essential to demonstrate that it consistently performs according to predetermined specifications. This process often involves rigorous testing and documentation.

Maintenance Best Practices for Air Compressors

Regular maintenance is critical for ensuring the longevity and efficiency of air compressors in pharmaceutical operations:

Routine Inspections

Conduct regular inspections to identify potential issues before they escalate. Checking for leaks, wear, and proper functioning can save time and costs.

Filter and Lubrication Management

Maintaining clean filters and ensuring proper lubrication are vital for optimal performance. Regularly replace filters and check lubrication levels as part of your maintenance schedule.

System Upgrades

Evaluate system performance periodically and consider upgrades to improve efficiency or compliance with new regulations.

Common Mistakes to Avoid When Choosing an Air Compressor

Selecting an air compressor can be challenging, and several common mistakes can lead to inefficiencies or compliance issues:

Neglecting Air Quality Standards

Failing to prioritize air quality can lead to contamination and product recalls. Always assess the air quality requirements before making a decision.

Overlooking Energy Efficiency

Ignoring energy consumption can result in higher operational costs. Consider energy-efficient compressors to minimize costs over time.

Inadequate Capacity Assessment

Underestimating your air demand can lead to insufficient performance. Carefully analyze your operations to determine the correct capacity requirements.

Future Trends in Air Compressor Technology and Their Impact

The landscape of air compressor technology is continually evolving, driven by advances in efficiency, automation, and sustainability:

Smart Compressors

The emergence of smart compressors equipped with IoT technology allows for real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime.

Sustainable Solutions

As the pharmaceutical industry moves towards sustainability, eco-friendly compressors that utilize renewable energy sources are becoming increasingly popular.

Advanced Filtration Systems

New filtration technologies are being developed to ensure that compressed air meets the highest quality standards, further minimizing the risk of contamination.

Frequently Asked Questions

What is the best type of air compressor for pharmaceutical applications?

The best type of air compressor for pharmaceutical applications often depends on the specific needs of the operation; however, oil-free rotary screw compressors are commonly recommended for their efficiency and air quality.

How often should I maintain my air compressor?

Maintenance frequency can vary, but routine inspections and filter replacements should typically be conducted monthly, with more extensive maintenance every 1 to 2 years.

What are the common compliant standards for air compressors in pharmaceuticals?

Common compliance standards include Good Manufacturing Practices (GMP) and ISO 8573-1, which outlines air quality classes for compressed air.

Can I use a standard air compressor in pharmaceutical processes?

Using a standard air compressor may pose contamination risks. It is advisable to select compressors designed specifically for pharmaceutical applications to meet stringent air quality standards.

What is the expected lifespan of an air compressor?

With proper maintenance, an air compressor can last anywhere from 10 to 15 years, depending on usage and the quality of the unit.

Conclusion

Choosing the right air compressor for pharmaceutical operations is a critical decision that can significantly impact efficiency, product quality, and regulatory compliance. By understanding the various types of compressors, key specifications, and maintenance best practices, companies can make informed choices that enhance their operations. Staying abreast of future trends and common pitfalls will further position organizations for success in this highly regulated and competitive industry. Prioritize air quality, efficiency, and compliance to ensure your pharmaceutical operation runs smoothly and effectively.

More news